Why are biomass and wood pellets widely welcomed all over the world?

There have been two main factors accelerating the development of pellet fuel market during the last decade-one is the increasingly improve- ment of cost and unstable price of fossil fuels, while another is people’s increasing attention of environment friendliness of wood pellets fuel. Certainly, wood pellets are also be appreciated by its high calorific value, easy production, low cost. The wide distribution of raw materials also gives pellets a social effect which can offer people an affordable fuel and creating a lot of jobs. If you are interested in the wood pellets, buy your own wood pellet mill and start your pellets business now.

What

Wood Pellet Mills

We Can Offer You?

Ring Die Pellet Mill, also called as round die pellet mill, runs under the effect of rollers and die. Compared with flat die pellet mills, the ring die pellet mill and its components are much bigger, heavier and more expensive, while the daily maintenance and adjustment of the machine is also very different. But relatively, the ring die pellet mill is higher productive than usual pellet machine. The low consumable cost and high efficiency are also reasons why people prefer the ring die pellet mill for mass commercial production.

Flat Die Pellet Mill is another different pellet mill that is appropriate for small scale production and/ or residential use. The compact and reasonable structure makes it small and light in weight for people to set and move it. Changeable components like rollers and dies are cheaper to purchase, easier to clean and faster to replace than those of a ring die pellet mill. The simple but scientific design makes you control the detailed processing procedure intuitively by watching the pelletizing chamber. This will help you know the machine clearly. If there are some producing troubles, you can solve it easily. With such a pelletizing machine, you can do your pelletizing with all possible materials conveniently.

How to Make Pellets from Wood?

Step1. Crush raw material into particles of appropriate size.

We have conducted a series of comparison tests for different pellet mill and common wood & biomass materials, and found that the pellet produced from crushed raw material has better and more consistent quality than those produced from rough raw materials. That is to say, before pelletizing, raw materials are necessary to check whether the size is suitable for direct pelletizing. Usually the answer is not. Then in this section, you can crush the raw material into particles firstly. You can choose the hammer mill, chipper or wood waste shredder for this purpose in accordance with your raw material.

Step2. Dry the crushed particles to required moisture content.

The moisture content of pellets can directly influence their quality- higher moisture content will make pellets lower the burning efficiency and produce more smoke, while less moisture content will make pellets hard to form. As our years of study and consultation experience shows, the proper moisture for wood& biomass pellets producing ranges from 10% to 15%. You can dry your materials naturally under the sun, or choose a hot air dryer to do it efficiently.

Step3. Compress prepared materials to pellets with a pellet mill.

The moisture content of pellets can directly influence their quality- higher moisture content will make pellets lower the burning efficiency and produce more smoke, while less moisture content will make pellets hard to form. As our years of study and consultation experience shows, the proper moisture for wood& biomass pellets producing ranges from 10% to 15%. You can dry your materials naturally under the sun, or choose a hot air dryer to do it efficiently.

Step4. Cool the finished pellets to room temperature.

After pellets are finished and get out from the pellet mills, temperature of them will be too hot to touch. Then you should put them in the open air to release heat and moisture naturally or apply a cooler for quick cooling.

Step5. Pack the pellets for storage or transportation.

Pellets cooled down can be packed for storage or transportation then. A packing machine will be needed to pack them quantitatively and sealed to avoid the damp and degeneration.

The Future and Economic Benefit of Wood Pellets

As an alternative to coal and petroleum, pellets are renewable, clean, and stable resources which have been wide accepted in North America. By using Wood Pellet Mill, this biomass fuel which is made from recyclable matters like wood scraps has been popularized to approximately 1,000,000 families in the U.S. for heating in freestanding pellet stoves, fireplace inserts, furnaces and boilers. Besides, you can also found the application of pellets in public places like schools.

Efficient

Wood pellets are efficient to burn because of the low moisture content and high calorific value compared with woodchips or cordwood. Virtually all of the material that combines a pellet can be burned and converted to heat.

Welfare of districts

Wood pellet mills can not only make people benefit, but also provide a quantity of jobs to support local economy development and energy independence.

Convenient

The small, uniform size of the pellets of pellets make them easy to be packed into bags for storage and transportation. You can put a ton of pellets into fifty 40-lb bags and place them orderly in a 4' x 4' x' 4' area without much effort. When you want to heat them, you can directly pour bags of pellets into a stove hopper, and regulate the rate that pellets flows into the hopper conveniently.

Environment friendly

Wood pellets are a green and sustainable energy source. When burning, it will realize carbon neutral for wood pellets.

Cost-effective

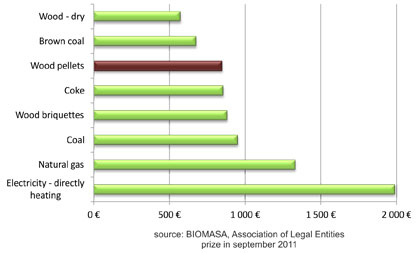

Not only featured by efficiency, wood pellets are also competitive in economic cost than other fossil fuels. They will cost less and save a lot of money for you.

Recyclable

Made from wood scraps or other organic matters, wood pellets can be used circularly. This has been proved by facts and many scientific research departments like the Pellet Fuels Institute.

| Fuel Type | Efficiency | Units to Produce 1,000,000 BTU |

Unit Cost | Cost to Produce 1,000,000 BTU |

|---|---|---|---|---|

| Wood | 60% | 0.08 cord | $180.00/cord | $14.40 |

| Wood Pellets | 80% | 0.08 ton | $220.00/cord | $17.60 |

| Natural Gas | 80% | 12.5 therm | $1.50/therm | $18.75 |

| Propane Gas | 80% | 13.5 gal | $2.00/gal | $27.00 |

| Coal | 75% | 0.05 ton | $200.00/ton | $10.00 |

| Fuel Oil | 80% | 9.0 gal | $2.00/gal | $18.00 |

| Electricity | 100% | 293.1kw | $0.10/kw | $29.31 |

From the above comparison, you can clearly identify the economical and

cost-effective superiority of wood pellet fuel.

cost-effective superiority of wood pellet fuel.

CONTACT US

View Larger Map

Add: Equipment Manufacturing Industrial Park, South of Pingyuan Road, Hi-Tech Development Zone, Anyang, Henan, China.

Tel: (86) 372 5081705 Fax: (86) 372 5951936

Email: info@pelletmillworld.com